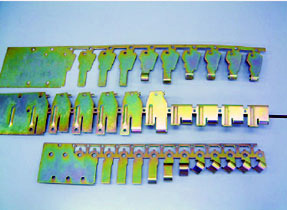

Start-to-finish production of the control wire cable bracket assembling

I produce bracket assembling to clamp a control wire cable on an assembly line from a die to press, welding, assembling and Progressive die press working is proud, but it is smooth and copes with small lot, the order of many kinds.

Lightweighting and the compactification of the car advance, and Body routing of the control wire cable is complicated still more recently, too.

Therefore, it is the situation that the complicated bending and curl with the shape increase to three dimensions of demands of the visitor and are it to the level of the limit by the sheet metal processing.

However, we pursue an advanced technique to be able to always solve the problem with a new idea.

Cable outer bracket

By an NC lathe, I process both ends and change three dimensions of pipes in a shape.

There be it and processes a press part and low and there be it and manufactures packing.

Parking foot & lever

I mold the materials of the large-blossomed chrysanthemum by a one-shot process.

Co2 welds each press part and paints a cation.

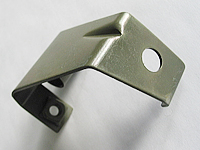

Opener hook

It is an example of our order forwarding processing to be the most proud.

Complete the press part by the process like 10 stages, and a group touches a plastic part and spring by manufacture work.

Cable bracket

In one of the characteristics of our processing, I put Carl in an order forwarding process.

In after process, I spot-weld a bolt nut.

Control lever

I punch stainless steel materials and go calking of spot welding and the brass.

It is used a lot for a ship-related part mainly.